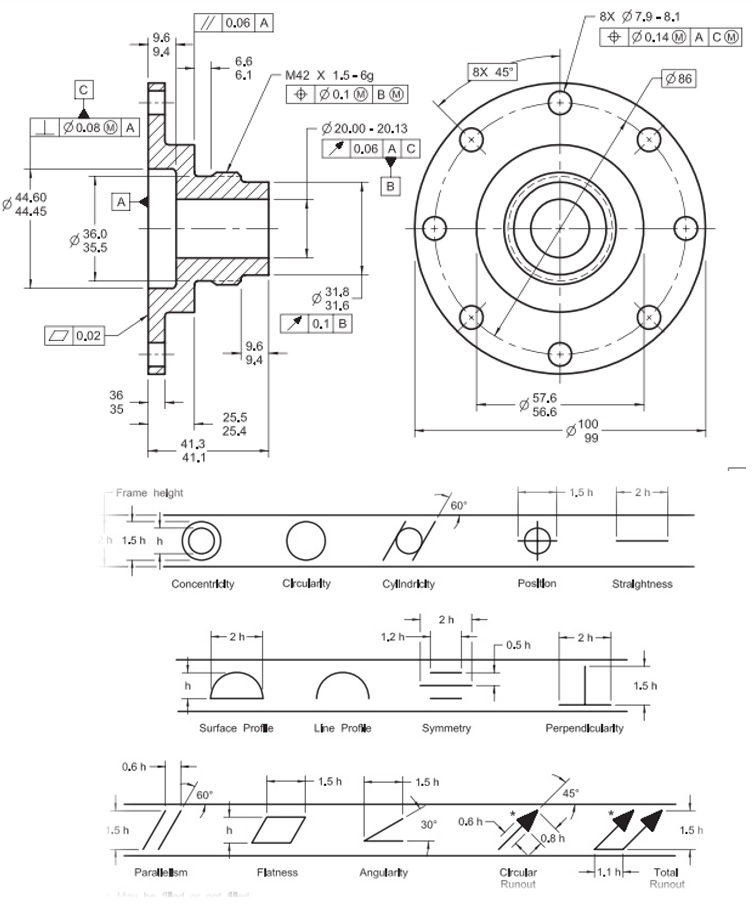

Geometric Dimensioning and Toleranincing GD&T

Comprehensive Course

GD&T is a universal design language applied by manufacturers around the world and is widely considered by mechanical engineers to be an essential tool for communicating design intent, ensuring parts meet the desired form, fit, function and assembly.

Download Brochure

Introduction to ASME Y 14.5M:2009

• What is GD&T?

• When should be GD&T used?

• GD&T vs Coordinate Dimensioning and Tolerancing

• Review of General Dimensioning

• Units of Linear and Angular Measurement

• Use of 3D CAD data/Model Based Definition

• Plans to Qualify Products

• ASME vs GPS concept of Tolerancing

Projections & Coordinate Systems

• Isometric, Dimetric, Trimetric Projections

• Cartesian, Cylindrical, Spherical

Geometric Tolerancing

• Fit types

• Symbols

• Feature Control Frames

Datums

• Establish Datum

• Origin of Datum

• Datum Targets

• Application of 3-2-1 rule, RPS, Networking,

• Datum Feature Selection

• Inclined Datum

• Cylindrical Datum Features

• Multiple Datum Features

Form Tolerances

• Circularity

• Straightness

• Flatness

• Cylindricity

• Profile (Bilateral, Unilateral)

Tolerances of Location

• Maximum Material Condition

• Concentricity/Co-Axiality

• Symmetry

Limit Tolerancing, ±Tolerancing

Geometric Tolerancing

Comparison

• Theoretically Exact Dimension

• Application of MMC concept vs Limit Tolerancing

• Effect of Maximum Material Condition

• Effect of Least Material Condition

• Effect of Regardless of feature

• Zero Tolerance

• Composite Tolerances

• Evaluation of CMM measurement/ Paper Gage Evaluation

Rules:

• Virtual Condition/Resultant Condition/Maximum Material Boundary/ Rule #1

• Datum Modifiers/Rule #2

• Pitch Diameter Rule

• The Virtual Condition Rule

Tolerance of Orientation

• Parallelism

• Perpendicularity

• Angularity

Run-Out Tolerances

• Tolerances of Run-Out

• Total Run-Out

• Concentricity vs. Run-Out Tolerance

The course covers the principles of GD&T, explaining how it is applied universally to manufacturing processes, and how to read and make interpretation for measurement processes, as well. It is designed to give participants a thorough understanding of GD&T that they can immediately use in their work.